As any builder can tell you, putting together an AR-15 rifle is a personal process. Everyone has their own methods and techniques, and individualism makes the finished product so much more rewarding. It’s difficult to convey the sense of pride and accomplishment that comes from shutting the bolt on a rifle you built with your own hands. No doubt there are plenty of great poetics about the relationship between a warrior and his weapon. Maybe that’s why it’s so frustrating when a build goes wrong.

Every day, rifle builders around the country make avoidable mistakes that create a disappointing—or even dangerous—final product. To quote Pat McNamara, “Experience is often something we get shortly after we need it.” In rifle building, this lesson can certainly sting. Many shooters spend thousands on their perfect parts list, only to find that nothing fits together. Experience reduces the chance of disappointment when parts hit the workbench, but research can help you avoid those costly first mistakes.

Here’s a few tips to help get your AR-15 or AR-10 build going in the right direction from the start. We’ll explain all the tools you’ll need for your best build, plus we’ll discuss some tricks we use when crafting our own rifles.

NO SHORTCUTS: TOOLS YOU MUST HAVE

The fastest way to frag your build is by going cheap on the tools. While you may not need a full armorer’s kit to build a rifle, there are some tools you will absolutely need. Substituting these bare minimums can jeopardize your build altogether.

You should always use these tools:

- Bench Vise (Preferably with Polymer/Nylon Jaws)

- Armorer’s Wrench

- Polymer-tipped Hammer

- Bev Block

- Punch Set

- Bit Driver + Bits

- Torque Wrench

- Eye Protection

You cannot apply torque without stability, so a bench vise and Bev Block are irreplaceable, especially during barrel installation. Insufficient torque will cause parts to slip loose, while excessive torque may bend the rifle’s receiver. To achieve accurate torque ratings, a quality torque wrench is a must. For everything else, an armorer’s wrench, a punch set, a bit driver, and a Delrin-tipped hammer can put the pieces together without scrapes.

When selecting an armorer’s wrench, favor the proven models like Magpul Armorer’s Wrench or Tapco AR-15 Armorer’s Wrench. A cheap wrench might get you through one build, but you don’t have to spend much more to get a tool that’ll last a lifetime. Wheeler offers their Delta Series Combo tool packaged with a torque wrench, if you need one. Wheeler also makes popular bit driver and punch set packages. The Wheeler FAT Wrench provides precise torque values for bit driving, and their punch set already includes a brass and polymer hammer. Finally, always wear eye protection. Small parts under spring tension can easily shoot out and surprise you. Plenty of builders have learned this lesson the hard way.

GETTING DOWN TO THE BASICS

The basics are the most important. Even expert builders can get tripped up in the simple traps, as competence creates confidence, and confidence creates assumptions. Assumptions make… Well, you know the expression. But what are the builder’s basic considerations?

The most common issue in rifle building is parts compatibility. If you are uncertain, you can always give us a call. Our customer service team will be happy to help you verify that your parts are compatible. From our experience, the most common issue comes with handguard selection, particularly when paired with billet receivers. Billet receivers look cool and add major flair to any build, but some handguard anti-rotation tabs refuse to fit their non-standard dimensions.

Similarly, handguard sizing can be a headache of its own. Undersized handguards expose the gas block to damage, while oversized handguards may extend beyond the muzzle threads. Unless you intend on recessing a suppressor or blast diverter into the handguard, this is a definite no-go. Sometimes, handguards can also cause problems when paired with piston gas systems or oversized gas blocks. Here, the internal measurement of the handguard may be more important than the external measurement.

The second most common issue in rifle building comes with parts planning. Your best builds start with a clear vision and end-goal, reducing wasteful parts replacements. Though waste doesn’t halt the build, repeated part swaps drain the budget fast. Every shooter adjusts their kit as they grow in experience and taste, but the phrase “buy once, cry once” is good advice. Pick something you know that you’ll like, lest you end up like this article’s author with a half-dozen different vertical grips stowed in clear plastic storage bins.

Finally, consider picking up extras on the small stuff. Tiny springs and pins can disappear in the blink of an eye. Even the most organized builders have had to put rifles on hold while waiting for replacement parts. Save yourself the frustration. Pick up some extra detents and springs with your order to prevent build-day roadblocks.

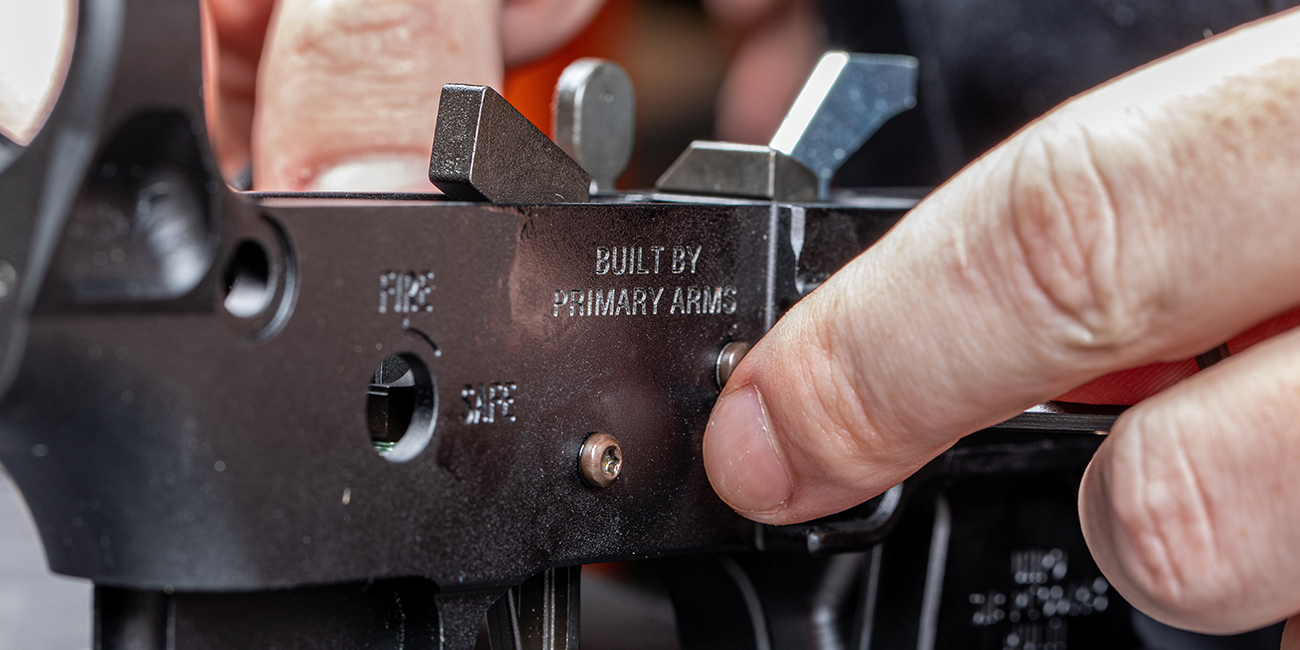

THE PRIMARY ARMS SECRET TECHNIQUES

Expanding on the basics, we’ve developed some of our own hacks for rifle building. Some are more common than others—and some may already be part of your procedures. This advice comes straight from a team behind our monthly rifle giveaways. Counting personal projects, our builders have 100+ completed rifles under their belt, so we’ve seen just about everything. Hopefully, our experiences can help you dodge some of the biggest build setbacks we’ve faced through the years.

For our first trick: the Real Avid AR-15 Pivot Pin Tool. Pivot pins can be a huge pain to install by hand, so we always use this tool to make the process easier. While a hex key can help manage the detent, any slip will fling it into the void. If you do pivot pins by hand, just be careful where you put your eye. We’re not joking when we say that detent can fly.

When working on threading, apply Aeroshell 33MS grease on the barrel extension, upper receiver threads, and castle nut. Not only will this protect against corrosion, but it’ll prevent seizing and improve your experience during barrel installation. Many receivers have been bent by overzealous builders fighting their threads. Never bust out a hammer for a task that should be done by hand.

That said, if you own a drill driver, consider a dimpling jig, such as the SLR Rifleworks .750” Dimpling Jig. A dimpled barrel makes the gas block install faster and guarantees solid fit without the risk of slippage. The dimpling process is easier than it sounds, and there is no risk to the barrel if you follow instructions.

Finally, we have painter’s tape for protection against marring and tool damage. Once you’ve scraped up the side of a receiver, you’ll never want to build without using some protective covering. Painter’s tape is an excellent adhesive that protects the finish of your rifle and shields parts against accidental scrape and impact. The Delrin-tipped hammer does a great job at reducing the scratches for lower parts installation, but a painter’s tape shield can boost confidence. If you need extra protection for areas like the bolt catch roll pin, electrical tape has more padding and the same low-strength adhesion.

WRAPPING UP

If you’re new to the building scene, you will probably make some mistakes along the way. Even experts slip up or miss a small detail. The most important thing is recognizing when to take a step back. Committing to the wrong process can do some serious damage to your wallet—especially when the right tool already exists. Inevitably, we circle back to tooling. If your parts fit, and you are using the right tools in the right circumstances, you will complete the build. At that point, it’s all about understanding your own tastes and the build’s aim. But never forget: even professionals keep touch-up pens at the ready. If you are having trouble, take a step back, give it a few minutes to settle, and think through your process before you put metal on metal. Resist the temptation to rush, no matter how close you are to completion. A rifle that works tomorrow beats a rifle that breaks today.